The Internet of Water Is Saving Lives While Battling PollutionThe Internet of Water Is Saving Lives While Battling Pollution

The old way of cooling buildings and industrial facilities is toxic and wasteful. Three companies have teamed up to combat the problem.

March 4, 2017

The Problem

A condition known as Legionnaires’ disease has made headlines after it killed a dozen people in Flint, Michigan in 2014 and 2015 and sickened hundreds in New York state last year. A rare but severe type of pneumonia, Legionnaires’ kills roughly one in ten people who contract it. The cause of the disease is the Legionella bacterial strain. Water loving, Legionella can contaminate hot tubs, water fountains, plumbing systems, and water-treatment cooling towers.

The name for Legionnaires’ disease goes back to the bicentennial of the United States. Some 4000 members of the Pennsylvania State American Legion, a group of World War II veterans, had traveled to Philadelphia for the American Legion Convention in 1976. Ultimately, more than 200 of those legionnaires fell ill while 34 others died after contracting a mysterious disease that would later be named after them.

Months after the outbreak, Joseph McDade, a scientist at the Centers for Disease Control determined that a bacterial strain was behind the epidemic. Working backward, he and other researchers eventually theorized that the bacterial strain likely came from the water-cooling towers on top of Bellevue-Stratford hotel hosting the American Legion event.

Fast-forward to today and such water-cooling towers are still one of the most common culprits for Legionnaires’ outbreaks. Perched atop most large commercial and industrial buildings, cooling towers are an intrinsic but often hidden part of the urban and industrial landscape. Mimicking the human body’s method of cooling with sweat, cooling towers are more efficient at cooling than using solely electricity.

Cooling towers, however, also can be breeding grounds for bacteria and even just determining that there is an outbreak of Legionella in a tower can be a challenge. “There’s no good test for it,” says Max Martina, president of Griswold Water Systems (GWS).

To control Legionella and other waterborne pathogens, building operators have traditionally used a toxic chemical soup. Biocides help control bacteria, but they tend to be corrosive to metals and can damage cooling towers, so operators also add corrosion inhibitors to the water.

A corrosion inhibitor was also at the heart of the Erin Brockovich case against Pacific Gas and Electric Company of California in 1993 immortalized in the eponymous film with Julia Roberts. PG&E had used a carcinogen, hexavalent chromium, to control rust in cooling water towers, which ultimately polluted the soil and groundwater.

While hexavalent chromium has since been banned for this use, there is still no perfect chemical solution for water-cooling towers. “There is this constant dance of injecting the cooling tower with chemical substances to control corrosion, bacteria, and scaling,” Martina says.

In some cases, the bacteria within cooling towers can become resistant to a given biocide—just as bacteria in humans evolves to resist antibiotics. When this happens, it requires building operators to rotate biocides.

Complicating matters further, a typical cooling tower uses vast amounts of water—often millions of gallons annually. Roughly one-third of this water is flushed down the sewer because it is so loaded with toxins that it cannot be recycled.

An IoT Solution

Several years ago, Martina decided to confront the problem through the use of strong electric currents to destroy bacteria rather than toxic chemicals. “The genesis of nonchemical is not new,” Martina says. “It grew out of a customer desire to eliminate these toxic chemicals from their facilities. I know of four people in this industry who have all died from pancreatic cancer. I am not casting aspersions on the industry but chemicals like isothiazoline are really toxic.”

The approach allows building owners to stop dumping chemicals into their water-cooling towers and to recycle any wastewater for gray-water applications. What is new, however, is the use of IoT to elevate the effectiveness of the treatment methodology and surpass industry standards.

Martina says that the IoT technology provides four benefits: First, it enables the company to ensure water savings takes place by tracking the efficiency of the cooling towers. Second, it enables the GWS service team to respond immediately if there is a system upset, thus reducing system downtime. Third, the technology can track whether the equipment is effectively treating the water. Lastly, the technology gives the company data to counter incorrect claims from competitors with real-time data.

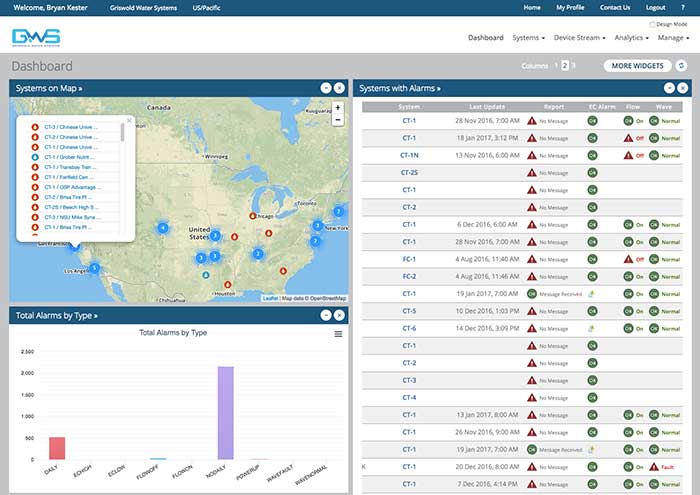

To integrate the technology, Martina enlisted the help of Hollis Controls, a systems integrator based in Southern New Hampshire, to configure the remote-monitoring technology and connect it to local networks. Hollis Controls, in turn, brought in See Control, now a part of Autodesk to offer the cloud-based platform.

While systems integrators like Hollis Controls specialize in writing firmware and software for hardware, they often reach out to partners when it comes to writing scalable web applications.

“The big problem in an IoT application like this is that if Max can get this out to the world population of cooling towers, at some point, the amount of data and analytics would break most conventional web applications,” says Bryan Kester, head of IoT at Autodesk. The company’s Fusion Connect platform enables companies like this to test a new market concept for cooling towers without worrying about having to scale the infrastructure, Kester says.

The Pushback

While GWS has installed the electric-based purification systems in hundreds of water-cooling towers, Martina says that large industrial chemical conglomerates have been pushing back. “It’s kind of a crazy industry,” Martina says. “When I got involved in this, I didn’t understand how cutthroat and aggressive it can be. I have a chemical service partner who has actually had his tires slashed by a competing chemical services company. There is some of that, but one would hope that it is in a minority of cases.”

Martina says that chemical conglomerates and their local agencies and affiliated chemical blenders are trying to discredit the technology. Others will try to entice their customers with tickets to prominent sporting events with the hopes that they will keep buying their chemicals. “We spend a lot of time talking about the science and the research that shows it works and 400 or 500 case studies—active users with references,” Martina says.

“What is scary is the chemical service provider does not have an incentive to save the customer water. Sometimes, the less-reputable firms will operate the tower less efficiently so that the tower consumes more water—and ultimately discharges more water and chemicals—thereby requiring the purchase of even more chemicals. This is known in the industry as ‘feed and bleed,’” he explains.

The Future

GWS technology is gaining traction, Martina says. “We reckon we’ve conserved more than two trillion gallons of water with several hundred installations we have internationally and probably 1200 tons of toxic chemicals have been eliminated as a result of that,” he explains. “Our next step is to integrate analysis for water metering for all of the applications we do.”

Autodesk is also reflecting on how to support them. “We have an artificial intelligence engine that we are testing that we will launch later in the year. We could invite GWS to be a beta user,” Kester says. “If they do want to get ahead of any predictive scenarios either around the quality of the operation or the water, we can use our AI engine for that.”

About the Author

You May Also Like

.jpg?width=700&auto=webp&quality=80&disable=upscale)

.jpg?width=700&auto=webp&quality=80&disable=upscale)

.jpg?width=300&auto=webp&quality=80&disable=upscale)