Researchers Create Process to Mass Produce Soft RobotsResearchers Create Process to Mass Produce Soft Robots

The weaving method enables mass production of robotics-compatible materials such as gel or rubber

.jpg?width=1280&auto=webp&quality=95&format=jpg&disable=upscale)

Researchers from the University of Virginia have created a new method of weaving soft materials, enabling mass production and what the team said could be a “soft robotics revolution.”

While soft robotics is a potentially significant industry in providing flexible, versatile gadgets, wide-scale uptake has proven difficult given the fact that they are typically hard to mass produce.

The team’s process meets this challenge by taking a weaving process traditionally used for rigid materials and transferring it to soft materials such as fabric, rubber and gel. These materials are compatible with electronic devices and gadgets, and mass production could open the door for widespread soft robotics production.

"Our work offers, for the first time, a state-of-art concept and route for weaving soft materials into 3D spatial structures," said Baoxing Xu, study co-author. "There are similar manufacturing approaches in industry, but all are designed for either rigid materials or nanoparticles, not for soft materials with continuous structures in forms such as film, ribbon and wire.”

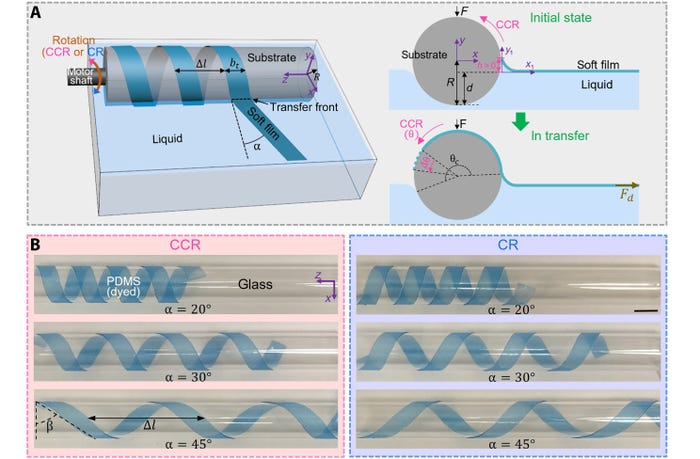

The new approach uses a liquid-based rolling transfer system that can make precise adjustments while weaving, making the manufacturing process fast and reliable.

Credit: University of Virginia

“We report a mechanical transfer route enabled by the rotational motion of curved substrates relative to the soft materials on liquid surface,” the team wrote in the study. “This transfer can weave soft materials into a broad variety of spatial structures with controllable global weaving chirality and orders and could also produce local ear-like folds with programmable numbers and distributions.

“We further prove that multiple pieces of soft materials in different forms including wire, ribbon, and large-area film can be woven onto curved substrates with various three-dimensional geometry shapes.”

In addition to creating soft robotics, the team said the process also has potential applications in developing wearable electronics, biomedical devices and other “internet-based products with complex outer surfaces.”

About the Author

You May Also Like

.jpg?width=700&auto=webp&quality=80&disable=upscale)

.jpg?width=700&auto=webp&quality=80&disable=upscale)

.jpg?width=300&auto=webp&quality=80&disable=upscale)