Robots Teach Themselves to Collaborate More Effectively

Research suggests small robots working together in industrial environments are better than one large robot

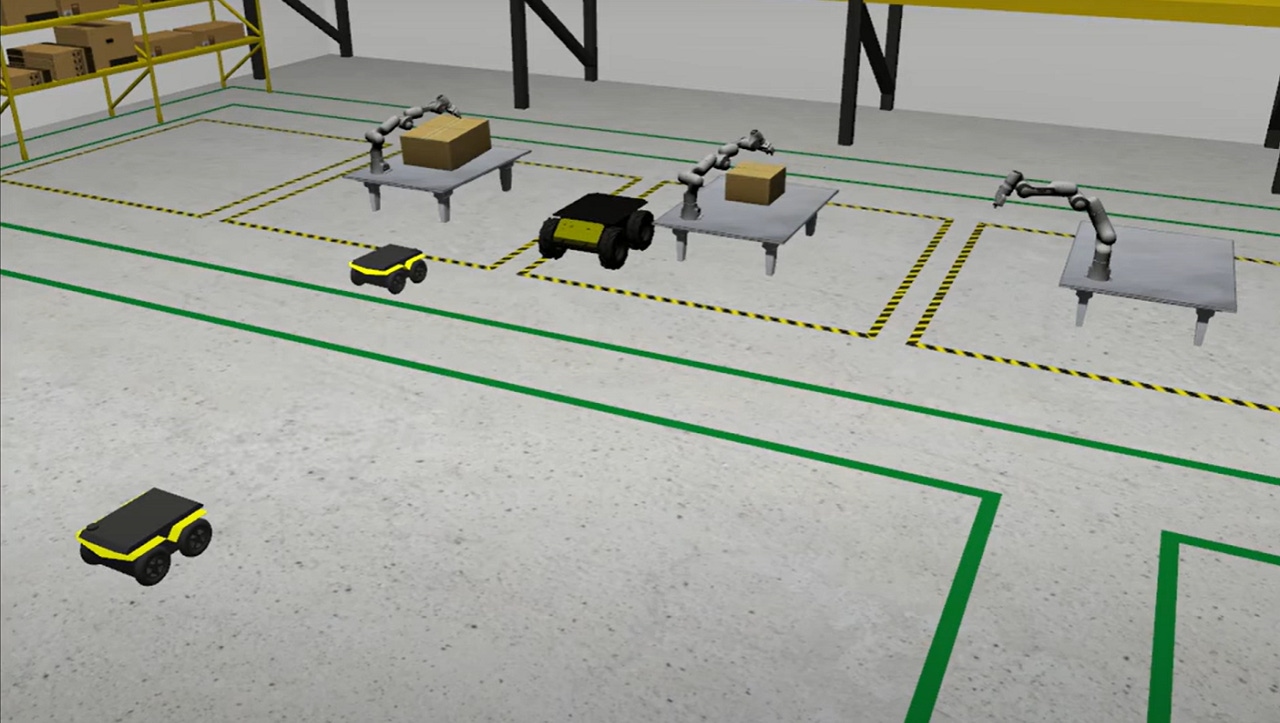

Researchers from the University of Massachusetts Amherst have demonstrated that programming robots to create their own teams and to voluntarily wait and work with their teammates results in faster task completion.

In an industrial setting, a team of robots can be less expensive to deploy but efficiently coordinating their diverse abilities can be difficult.

To address this challenge, the researchers created a learning-based approach for scheduling robots, called learning for voluntary waiting and subteaming (LVWS).

The method taught the robots to voluntarily wait for the other robots when optimal, for example, to complete a bigger task together rather than immediately performing a smaller task.

The LVWS approach was tested with six robots given 18 tasks in a computer simulation. The results were compared with four other methods. These were then benchmarked against a known, perfect solution for completing the scenario in the fastest amount of time to see how suboptimal they performed in comparison.

The new method was 0.8% suboptimal, compared with 11.8% to 23% for the other methods, meaning it was close to the best possible theoretical solution.

“There’s a long history of debate on whether we want to build a single, powerful humanoid robot that can do all the jobs, or [should] we have a team of robots that can collaborate,” said the study co-author Hao Zhang, who is an associate professor in the UMass Amherst Manning College of Information and Computer Sciences and director of the Human-Centered Robotics Lab.

Zhang’s colleague and co-author, Williard Jose, a doctoral student in computer science at the Human-Centered Robotics Lab said the research demonstrates that collaboration can be more beneficial.

“Instead of a big robot performing a particular task, it would be more beneficial for the small robot to wait for the other small robot and then they do that big task together because that bigger robot’s resource is better suited to do a different large task,” he said.

Jose added that despite it being possible to determine an optimal answer, robots still need a scheduler because the exact solution takes very long to compute, whereas, with larger numbers of robots and tasks, the optimal solution can be achieved in a reasonable amount of time.

When looking at models using 100 tasks, where it is intractable to calculate an exact solution, the researchers found the LVWS method completed the tasks in 22 timesteps compared to 23.05 to 25.85 timesteps for the comparison models.

Zhang said he hopes the work, which was funded by a DARPA Director’s Fellowship and a U.S. National Science Foundation CAREER Award, will further the progress of teams of automated robots working together.

About the Author

You May Also Like