Become a Live Aerospace and Defense Business

December 23, 2016

Sponsored Content

The business and IT environment is changing as the world economy goes digital, and aerospace and defense (A&D) enterprises face competing imperatives. Customers expect the latest product innovations to improve performance and end-customer experiences, and want outcome-oriented service models to reduce cost and risk. Managing design and build programs and globally distributed supply chains is more complex than ever, especially while searching for the right business model mix to ensure growth. At the same time, A&D organizations must streamline core processes from design to aftermarket and build a modernized, agile production environment that can scale to varying rates across program portfolios and reduce waste.

A&D enterprises are looking at strategies to embrace digital transformation – and ultimately become live businesses. At the center of this idea stands a fully connected digital architecture that helps drive operational excellence, re-imagine business processes and business models to power growth, and delight end customers.

What’s it mean to be a live business? It means on-the-fly access to all aspects of the enterprise in every format and detail, and agile planning synched in real time with closed-loop operations that continuously improve outcomes and drive consistency. It means accelerated financial and project reporting (where traditional batch processes are replaced by online access, even at the volumes typical for A&D), and interactive digital boardrooms.

Becoming a live business means gaining real-world insights by embedding Internet of Things (IoT) systems and enabling machine intelligence and data science on Big Data, to create comprehensive virtual models of complex physical systems. And it means a digital network for risk-based supply optimization, cloud-based global logistics and track and trace of critical assets, and new business models driven by the value of digital information.

Digitalization enhances existing processes through a fusion with IoT and business networks to make them more responsive and insightful – more “real world.” But it doesn’t stop there. Going digital offers opportunities to create new revenue streams with “information as a product,” using information collected and consolidated from different systems and exchanged on digital aviation commerce platforms.

Drive operational excellence

Being a live business also means real business benefits for A&D organizations. Go digital and you can:

Deliver faster on record-high production rates by virtually optimizing capacity from your existing assets

Drive product innovation while cutting costs

Address supply-chain complexity and risk through global transparency, alert-driven control systems, and network-level intelligence

Manage the transition of the A&D workforce

So how can you get there?

A digital core for innovation

A digital core enables real-time A&D operations, with in-memory computing power and end-to-end business processes and governance based on consistent data models, and functionality for real-time simulations and data science such as predictive analytics. With a digital core, you can react to dynamic conditions, make smart decisions, assess opportunities quickly, and streamline processes to eliminate waste and increase throughput. Controllers and program managers can present live data in management meetings and identify exceptions in real time. You can optimize project costs and scheduling, improve data quality, modernize processes, and support digitized smart products. Next-generation production planning facilitates faster planning cycles from master to detailed production scheduling, improving overall planning quality and accuracy, and integrating capacity constraints at all stages for more feasible plans.

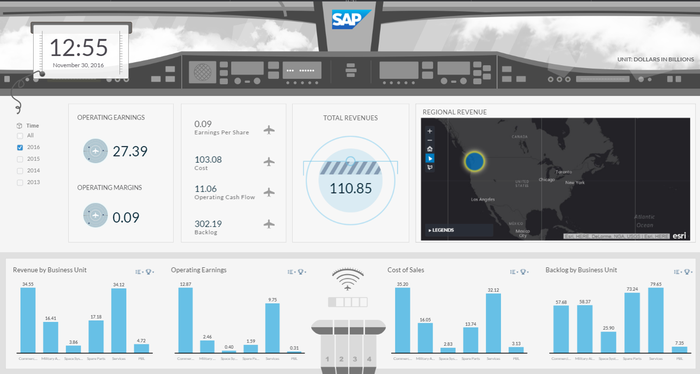

It’s not a boardroom – it’s a control room

Heterogeneous reporting solutions and outdated content can bog down meetings and hamstring decision making. A digital core and innovative software solutions can transform executive meetings from one-way presentations based on static media to real-time interactive discussions. With software for planning, simulation, and data exploration, you can understand the past, predict the future, and drive execution, leading to more impactful meetings and empowering leaders to monitor and drive change. For example, during meetings you could access financial performance data and get details into business-unit level contributions, broken down into commercial airplanes, military airplanes, space systems, spare parts, and services. Or you could drill down into specific costs for highly granular details – and valuable insights.

Re-imagine processes with IoT connectivity

Close the operations loop through IoT connectivity, automated processes, and machine intelligence and Big Data science, and change how A&D products are built and serviced. Smart, connected factories with advanced automation and integration of shop floor processes deliver granular data for optimizing products and processes and proving compliance – for example, enabling nonconformance management with early warning systems and predictive quality controls.

Enabled by a digital core, aviation companies can also perform real-time equipment health monitoring and fleet management and original equipment manufacturers can improve reliability programs. You can combine high-volume IoT sensor data, logistics and geospatial information; financial content; and maintenance, repair, and overhaul data for enhanced, proactive decision support. Aircraft sensors can feed telemetry data (temperature, vibration, pressure, etc.) and fault codes into a digital platform that can enable the visualization of this data, predict impending failures, and issue alerts that can trigger maintenance actions. Enabling the digital aircraft lets you increase equipment uptime and avoid unplanned maintenance disruptions. You can better execute on outcome-based contracts, gain insights into aircraft reliability, reduce risk, and increase profitability.

Delight customers and grow your business

Many A&D stakeholders agree there is substantial potential in expanding business views across the enterprise and designing network value streams that enable collaboration and benefit all business partners. But there are obstacles to overcome, including isolated processes and systems, a lack of cost-efficient collaboration, security issues, and master data standards.

A digital platform that connects a digital core with the IoT, many-to-many business networks, and integrated electronic commerce solutions provides the necessary framework for highly digitalized collaboration. Such a platform simplifies and harmonizes secure data exchange among companies and acts as a universal data hub to fuel new digital business models that add value beyond individual systems and focus on customer outcome. What’s more, a digital aviation platform not only lets multiple companies collect and access harmonized data from the network. It fosters true innovation through the creation of new applications and digital services that provide custom-tailored benefits for businesses and customers.

Turn aircraft maintenance operations into a live process with a digital platform, and collaborate through a digital network to reduce operational costs and achieve higher asset utilization. You can move quickly to adopt and take advantage of new technology and software, while reducing infrastructure investment and costs.

Discover the customer success stories, technology, and partners behind Live Business. Join us March 6–8, 2017 in San Diego, CA, at the fourth SAP Aerospace & Defense Innovation Days.

You May Also Like