Unmanned Bulldozer Developed in ChinaUnmanned Bulldozer Developed in China

It's claimed to be the first driverless bulldozer of its type in the world

In recent years, we’ve become accustomed to the idea of autonomous cars, shuttles, trucks and even road sweepers.

Now the driverless bulldozer has become a reality in China.

A team from the Huazhong University of Science and Technology (HUST) and manufacturer Shantui Construction Machinery has produced what is claimed to be the first driverless bulldozer of its type in the world, and it has already been tested extensively, with more than 100 assignments completed.

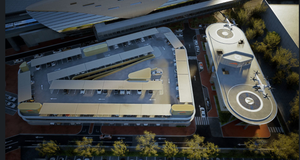

The bulldozer, which carries the codename DH17C2U, was developed at the National Digital Construction Technology Innovation Center at HUST in Wuhan. It can work autonomously with no remote operation.

Work started on the bulldozer in 2019 and since then functionality such as pushing and levelling has been fine-tuned over a series of trials, some carried out in extreme conditions, including temperatures as low as minus 10 degrees.

In late July, version 2.0 of the driverless bulldozer completed testing in Shandong province, where it demonstrated its ability to accurately execute operating instructions.

Its ability to work unmanned comes via a high-performance computing system and a precision positioning system that uses Chinese Beidou sat-nav tech. It also supports communication via 5G. Shantui has conducted extensive research in intelligent and autonomous transport in recent years due to the high demand for drones.

Although we have seen versions of bulldozers with automated functionality before, HUST and Shantui hold the intellectual property rights for this version, and it is being promoted as one of the university’s ‘top 20 AI achievements.’

While a self-driving bulldozer is expensive to develop, the desire to bring one to market is driven by its potential to deliver safety benefits and financial savings.

It’s claimed the HUST/Shantui bulldozer would eliminate the need for human operators to perform boring, repetitive tasks, improving safety. It would also help avoid exposure to potentially dangerous operating scenarios and even pollution.

And according to HUST, based on three shifts over 24 hours and a daily wage of about $150, labor costs for operating a traditional bulldozer can easily stretch to more than $160,000.

The next step for the autonomous bulldozer is to increase its exposure to different operating scenarios. Later this year it is likely to be deployed in mines, road traffic engineering and infrastructure construction.

The ultimate goal is to bring the vehicle to market. Shantui is one of the top 50 construction machinery manufacturers in the world, with the capability of building 10,000 bulldozers annually. The company says the unmanned bulldozer will be offered for sale as soon as the technology has matured.

About the Author

You May Also Like