IoT in Logistics: Hackathon Team Aims to Slash Food WasteIoT in Logistics: Hackathon Team Aims to Slash Food Waste

A vast sum of produce ends up spoiled during shipment. A team competing in a hackathon has set its sights on the problem.

August 27, 2019

It seems that every time there is a hot new technology, the supply chain emerges as a possible beneficiary. In the early 2000s, Walmart asked its suppliers to deploy RFID technology in pallets and cases. Last year, when blockchain hype likely reached its zenith, there was similar excitement about the potential of digital ledger technology to help drive traceability in the supply chain.

Of course, the Internet of Things and the broader field of artificial intelligence have a host of potential supply chain applications.

It is therefore fitting that the supply chain emerged as one focus area for a recent hackathon organized by Softweb Solutions, an Avnet subsidiary. Known as IoTConnectNXT, the hackathon attracted some 150 participants divided into 16 teams to explore an array of IoT-centric projects. Kicking off on August 19, the event lasted five days. As of August 26, the event’s jury had not decided which team will win the contest.

A team calling itself “Team Sherlock” aimed to leverage IoT in Logistics to help better preserve the freshness of produce and other goods shipped via the so-called cold-chain, or temperature-controlled supply chain.

Despite many attempts from a variety of organizations to apply various technologies to cut down on food waste, the problem persists. A recent study from BCG reports the problem is especially acute for produce. In all, 46% of total produce is lost each year, according to BCG. In all, it estimates some 1.6 billion tons of produce is discarded globally internationally.

Team Sherlock branded its approach to combat the challenge “FreshNxT,” which offers logistics companies real-time information based on the state of their delivery to “enable them to make decisions impacting the quality of produce and also make changes to their inventory or rerouting decisions,” said Dhiren Raval, program manager for IoT and events director at Softweb Solutions.

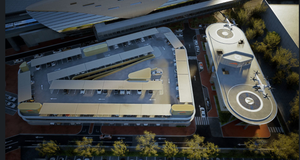

IoT and technologies such as predictive modeling apply to the entire supply chain for food and perishable goods, ranging from farmers, warehousing firms, processing and distribution companies and retailers. Team Sherlock is initially focusing on the supply chain for inbound logistics to provide real-time tracking and monitoring.

The team decided to leverage multiple sensor-enabled pallets, carriage carts that store the produce in transit and measure moisture and temperature trends in real-time. The strategy for using IoT in Logistics can combine that information with historical quality data graphs to ensure that the current status correlates to a given standard. The platform ingests multiple datapoints as produce makes its way from Point A to B. It uses proprietary freshness trend modeling for moisture and temperature tracking.

Raval said the approach supports initiatives described in the Food Safety Modernization Act, a piece of federal legislation that became law in 2011. The law recommends extensive end-to-end monitoring for produce. “Our vision at FreshNxT is to have a complete ecosystem of end-to-end solutions,” Raval said.

For its IoT in logistics approach, Team Sherlock leveraged Avnet’s IoT Connect platform to enable real-time alerts and reporting of potential problems. The software also integrates with Salesforce to support the creation of problem tickets.

About the Author

You May Also Like