Digitization Plus Analytics Mindset Is Engine for IoT Success

A majority of organizations have digitized and enlisted data to drive decision making. But only some have determined how to make their data truly actionable.

March 3, 2021

Key takeaways from this article are the following:

Recent survey data indicates that most engineering, construction and infrastructure companies have digitized with zeal.

But despite digitization efforts, only about one-third have data-driven strategies that improve performance in companies’ key performance indicator areas, such as cost, performance and schedule.

High-performing companies develop data strategies and cultures and adopt tools such as control tower technology.

In industries such as engineering, construction and public infrastructure – often dominated by paper-based processes – digitization projects are crucial to industry progress.

But many of these projects were put on hold in 2020 because of budget constraints and economic uncertainty in the wake of COVID-19.

Indeed, more than 60% of projects in factories, mines and refineries or for telecommunications and infrastructure will be delayed or put on hold in the months to come, according to a new Accenture report surveying some 700-plus executives on digitization initiatives, from IoT projects to data visualization and control tower technology adoption.

At the same time, the majority of organizations have embarked on digital journeys. The problem is that many of these journeys don’t generate adequate ROI, the report found.

“There is a lot of investment in digital technologies to make improvements, but they aren’t always panning out,” said Andy Webster, managing director of capital projects at Accenture.

This has created stop-and-start tendencies for many of these companies. “There was a lot of consternation about continuing to do projects, and many have slowed down,” he said.

That points the way to the importance of a data-driven strategy to drive success.

According to a recent McKinsey report, 60% of high-performing companies have strategies that are “mostly aligned” and for data, analytics and business objectives, compared with just 44% of other companies.

Increasing Digitization Doesn’t Ensure Successful Data-Driven Strategy

That aligned strategy continues to elude many organizations.

According to the Accenture findings, some 90% of surveyed organizations have introduced digital capabilities such as connected sensors, 4D and 5D visualization, and other automated technologies.

But, while companies have embraced connected things and data collection, they haven’t seen the full impact of digitization projects.

“Being able to deliver on those objectives is key,” Webster said.

Strikingly, while many survey respondents are gathering data on key performance indicators (KPIs) – for example, keeping projects on schedule, reducing costs, or performance of assets such as power or connectivity – they haven’t gleaned a performance boost from data gathering.

In Accenture’s survey, 90% of companies collect data; but only one-third “see the needle in project performance move as a result of investment,” Webster said.

What Drives High-Performing IoT, Digitization Projects

Webster said that while the majority of organizations have gathered data, higher-performing, data-driven ones have common attributes that enable them to use data to drive their business objectives; similarly, lower performers haven’t connected data gathering to their KPIs. “They were collecting the information but haven’t institutionalized that data in the processes that use it,” Webster said.

Three factors contribute to the institutionalization of data in processes:

Committed C-suite. Webster said that leadership factors greatly in data-driven success. He noted that in the outperformer group, three-fifths have a C-level sponsor for digital transformation. In the rest of the pack, only one-tenth have a sponsor.

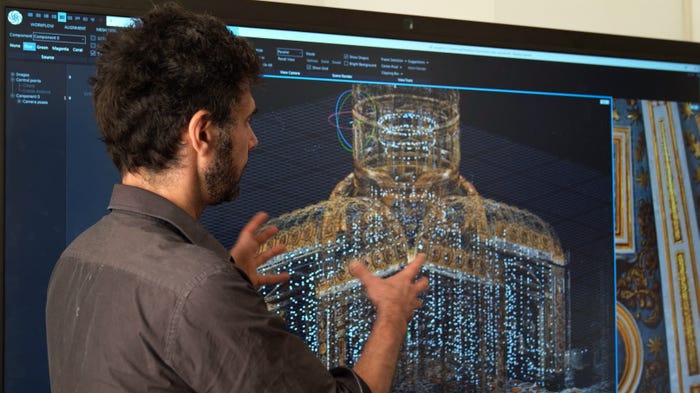

Data-sharing infrastructure. Successful companies invest in IoT technology for edge analytics and on-site, real-time delivery of data, and these companies have invested in IoT technology for on-site delivery, then using data lakes and cloud technology to better harvest data. Companies also use 4D and 5D tools to overlay data on certain operational processes.

Data-friendly talent. Outperformers invest in data stewards and talent who are digitally savvy, Webster said. McKinsey’s study also found that high-performing organizations supported a culture of analytics. In McKinsey’s report, 53% of leading organizations’ managers championed analytics, compared with 38% at average-performing organizations.

Data Integration Key Foundation for Data-Driven Practices

Other key obstacles in bringing data-driven practices to organizations are organizational silos and lack of digital practices.

“If you were to look at a traditional project … they are very siloed,” Webster said. “It’s an area where they strive for functional excellence within the silo, but they haven’t really stitched together the end-to-end value chain more effectively across silos, and then … across the project ecosystem [by extending to other suppliers, companies].”

Webster noted that organizational silos are consistent with a lack of executive sponsorship for data-driven strategies.

“It’s difficult to navigate across silos if you have sponsorship only within the silo,” he said.

Companies have begun to use technology to bridge these silos, though. In particular, control tower technologies to help stitch these silos’ information together.

“We see control-tower-type capabilities as a critical enabler of better awareness and decision-making in projects. The supply chain can negatively impact a project – late materials to a project can have a severe negative impact on the project,” Webster said.

That’s consistent with other market data on control tower technology adoption.

An April 2020 survey indicated that more than 85% of companies did not have a control tower, but more than 70% indicated an urgent need for control tower technology to gain visibility and control of supply chain data – a need accelerated by COVID-19.

“We see some mature clients using control-tower-type technologies to do network deployment – though they may not be calling it that,�” Webster said. Less-mature companies haven’t yet seen the virtue of control-tower technologies, however to gain visibility into projects as a whole. So too, many continue to struggle with siloed, fragmented data that control towers seek to integrate.

About the Author

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)