Buzzwords Alone Don’t Drive Real Business ChangeBuzzwords Alone Don’t Drive Real Business Change

Conversations about the digital future tend to be nebulous, but they don't have to be.

April 20, 2017

In the early and mid-2000s, it seems everyone talked about making the shift to the cloud. “But it wasn’t clear what cloud was,” says Jay Allardyce, chief operating officer for GE Power Digital Solutions. “It seems like cloud is everything.”

The story is similar for Big Data and IoT. When it comes to the former, people go on talking about petabytes, yottabytes, and brontobytes or about leveraging the power of IoT to digitally transform their business. But with any technological buzzword, cutting through the hype and noise to change your organization requires a careful strategy and a focus on day-to-day operations. “What is changing you as an individual to do something different?” Allardyce asks. “At a basic level, it is behavioral change. You did something one way yesterday, and you are going to change because of digital, IoT, cloud, or another one of those flavors tomorrow.”

In the industrial realm, embracing IoT requires companies to modify the culture of their organizations. Successfully implementing the Industrial Internet of Things (IIoT) requires a multifactorial approach— thinking about the business case, the network of things, data collection, and translating that data into actionable information. On top of that, IIoT projects require unprecedented collaboration among various stakeholders.

What is changing you as an individual to do something different?

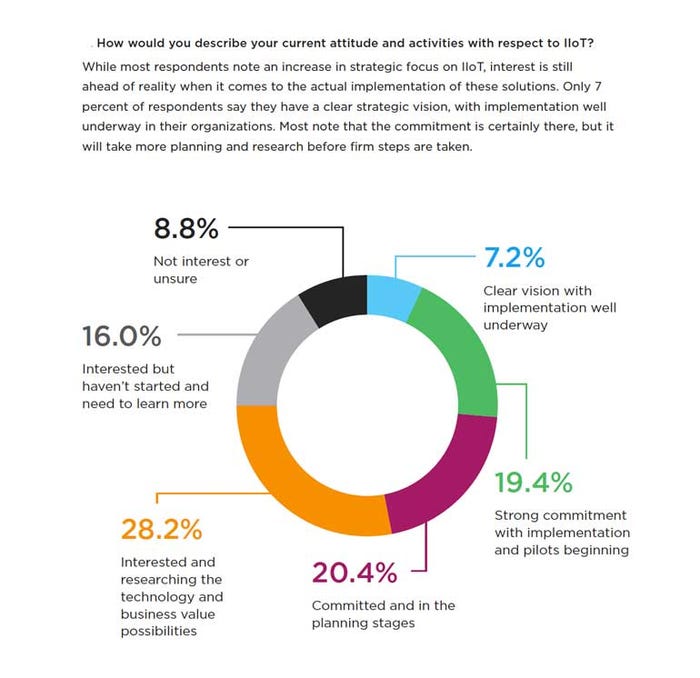

It’s no wonder then that so few of the respondents in “The Impact of Connectedness on Competitiveness” survey reported having a clear vision of IIoT. The industrial sector is still early in the adoption cycle of the technology, and many of the most successful adopters of the technology aren’t sharing their secrets.

“The hardest thing for industrial companies to address regarding IoT is creating a competitive advantage in a new, nascent market,” says Dave McCarthy, senior director of products at Bsquare (Bellevue, WA). “It’s easy to start collecting data without a plan for how you’re going to leverage it, and those that do are often reluctant to share details about IoT deployments because of their strategic nature. The successful companies start with a business outcome and work backwards to get to the right technology that can improve those processes.”

Another wrinkle is that one of the biggest benefits of IIoT is predictive maintenance—36% of the study participants expected the technology to lead to improved equipment uptime and performance via predictive maintenance and asset management. But achieving this goal can be trickier than it sounds. When we asked executives about their company’s ability to use real-time insights and systems monitoring, only 12% said they were doing an excellent job. About one-third ranked their abilities as “moderate/improving,” while 20% evaluated their ability here as “weak” and another 10% reported that they were “very weak.”

[Related: Check out BPI Network's in-depth IIoT research report.]

Many companies with IIoT technologies succeed in using sensors to gain visibility of their production facilities, but that’s not enough, says Hans Thalbauer, SVP, Extended Supply Chain and Internet of Things at SAP. “It is not good enough to monitor. The real thing is the action—combining the ‘things’ with business processes to provide the real outcome.” Thalbauer said the situation reminds him of a Geico ad depicting a patient at a dentist’s office. “The guy is sitting there with his mouth wide open. ‘You have one of the worst cavities I have ever seen,’ says the man who is presumably the dentist, before saying: ‘OK, have a good day!’ Taken aback, the patient asks: ‘Aren’t you going to fix it?’ ‘Oh, I am not the dentist. I am just a dental monitor. I just tell you when you have a bad cavity,’ before walking away to go grab lunch.”

The same principle applies to the Industrial Internet of Things. According to one story, British technologist Kevin Ashton came up with the term in 1999 while working at Procter & Gamble. It seems that a certain shade of lipstick in the cosmetic line he managed apparently was mysteriously out of stock and he wanted to use technology to figure out why. In other words, the use case was all about monitoring. But instead of thinking of the buzzword in terms of how it was defined decades ago, I encourage you to flesh out your vision of the future. How will you dazzle your customers? How will you use the supply chain as a competitive advantage? How will you create new business models? While few people go out and shop for Industrial Internet of Things technology, after mulling questions like those, IIoT will likely be the heart of most of your answers.

About the Author

You May Also Like